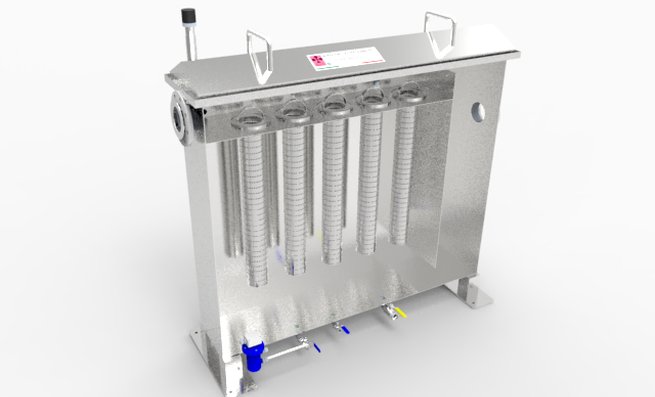

Deaeration and filtration for lubrication systems – DWA separator

DWA (dirty water air) SEPARATOR eliminates the impurities from the mineral oil used by the plant, whether they are made of air, water or solid particles, through a system of filtration, deaeration and condense separation. It can be installed on existing tanks and it integrates the pre-existent plants; or in inside the newest tanks.

Its peculiarity is the fact that it can add the filtration at the beginning of coalescence, without running into the inconvenience of the classic return filters. In addition to stopping the particles of solid pollutant, there is a deaeration and a consequent elimination of the condensations that cause the contamination of the lubricant oil.

This original principle of operation was validated by I2T3, the instrumental institute for the university-enterprise technologic transfer of the University of Florence, but most importantly it is guaranteed by many, many installations we carried out both in Italy and abroad.

DWA Separator is advantageous and convenient because:

- contributes to the reduction of the nominal capacity and the volume of the latest generation of tanks, determining

- considerable savings regarding energy consumption and environment

- it considerably reduces the presence of water in oil

- it preserves the components of the plant (pumps, etc.)

- it reduces the consumption of In –Line filtration elements

- the increase the life span of oil charge

- it is easy to maintain since it is equipped with washable filters made in stainless steel

- it can be mounted as an additional unit of existing plants.